Before we talk about anything “social” as it pertains to the supply chain, let’s start off with just the plain ‘ol supply chain. There are a few definitions of “supply chain” but I like the one put forth in the book “The New Supply Chain Agenda” by Rueben E. Slone, J. Paul Dittmann, and John T. Mentzer which is:

“The activity that manages the flow of information, money, and material across the extended enterprise, from supplier through the functional silos of the firm to customer.”

Here is the visual I reproduced from the book which shows how materials and information should flow across the extended enterprise.

If we take a look at the above graphic we can see that products flow from the firm to the suppliers to the end customers. However, the business decisions around those products are based on information that flows from the customers to the suppliers to the actual firm; this dictates the strategic requirements necessary to make the supply chain “work.” The supply chain actually includes quite a lot of things such as:

- physical capital needed to manage and distribute that inventory

- manufacturing products

- slow moving/fast moving inventory

- transportation costs

- warehousing costs

- inventory turnover

- pretty much anything that has to do with any type of inventory

I’m by no means a supply chain expert and I know this stuff can get pretty complex but hopefully everything makes sense so far.

So if this is a supply chain then what’s a “social” supply chain?

Social supply chain management seeks to incorporate social data, network, and interactions into the supply chain. So what does this mean?

Let’s say you release a new product that is being distributed across a particular region, say California. Through monitoring the social web your organization discovers that there is a strong demand for the product in another nearby geographic location such as Nevada. You take this information and alter your supply chain dynamically to address this growing demand. You might alter a delivery route that stops by Nevada before heading to San Francisco. Again, the idea here is that you are able to alter your distribution based on social data.

Let’s take another example. Say you are looking to distribute products to a particular area and then based on social data you find out that your shipments won’t get there in time (due to weather, a natural disaster, or anything else) you can alter your supply chain based on that information to mitigate time delays and loss. (other types of risk identification are also possible).

The “social” supply chain also leverages supplier communities to make business decisions and improvements to the supply chain, think of your standard enterprise collaboration solutions but geared specifically at suppliers. Vendors such as Rollstream and Elemica specialize specifically in these supplier community solutions (which you can learn more about by visiting their sites).

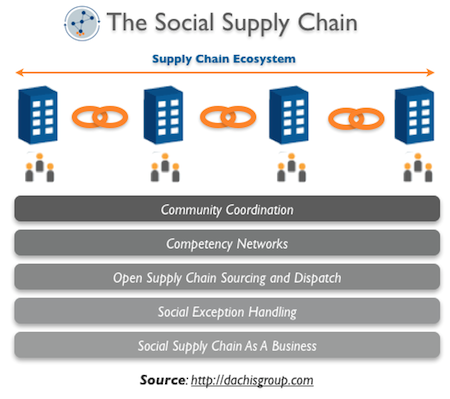

There aren’t many visuals out there which really show how a social supply chain works or what it looks like however I did find one create by Dion Hinchcliffe which is a good start (which came from this post).

There’s a lot to be said about the social supply chain but if we look at the image created at the top which depicts a traditional supply chain, then how exactly is a social supply chain different? In my opinion there are two differentiating factors of a social supply chain:

Feedback mechanisms

As Dion mentioned in his post which I linked to above, feedback mechanisms can vary from all sorts of channels and mediums, whether they be APIs which developers can use to build mashups or whether that feedback comes from supplier communities or directly through a tweet. I don’t want to get into too much detail but many companies are now using RFID tags which basically give products a “voice” to communicate with their handlers (you can find out everything you need to know about a product or inventory based on an RFID tag). The key here are the new channels and methods of information flow and feedback, but at the end of the day they still fall under the basic premise of how a regular, plain, old, boring, supply chain functions.

Response time

Responses to changes in the supply chain or to suppliers can now be made in almost real-time via social channels, this was not possible even 3-5 years ago. It’s the same concept that we apply to basic social media interactions. Nowadays you can find out about and respond to someone in real-time that is talking about you on the web.

I’m still doing a lot of research/learning around social supply chains but the concept and idea is very interesting. I don’t think at this point in time (as with Social CRM) there is a definite list of characteristics that make a supply chain “social.” I also didn’t come across any companies that are using social supply chains (perhaps components such as RFID tags). This is going to be a new topic I’m going to start exploring here along with Enterprise Resource Planning (ERP) so stay tuned!

Some thing to think about, how does this fit with Social CRM, what are the social supply chain use cases, how does the social supply chain integrate with an organizations CRM and/or ERP systems? I certainly don’t have all the answers here, but it’s interesting to think about these things as we continue to see the evolution of business.

In the meantime, what do you think about social supply chain management, does it make sense, do you even think it really exists? The floor is yours!

The problem with social add-ons to any form of enterprise application is that it creates just a huge amount of additional data that is pretty much useless for the business and its relationships with customers and partners if that relationship cannot be built and fostered by any other means.

Real-time response to customers and suppliers is not achieved by any social channel but rather by an underlying system that allows a consolidated approach to all business communication, its context and the related business processes. On the contrary, most of social media “data”, or rather, flurry, flows into those functional silos mentioned, thus creating additional sub-silos and further eluding an effective closed-loop communication along the whole supply chain.

A bit of a stretch in reality.

Social supply chain solutions actually help fill the gap that exists between manual and transactional business-to-business processes and as a result are being used to enable real-time response to customers or suppliers.

Despite years of investing significant time and effort in ERP and eProcurement solutions, many Global 2000 organizations continue to face a fundamental challenge – they cannot collaborate effectively with their business partners. Most B2B processes are manual, resource-intensive operations that are typically resolved via numerous emails, faxes, and phone calls.

Social supply chain solutions addresses these problems by optimizing the B2B relationships with online collaboration. Here's a great example of how a Fortune 500 companies was able to engage their supplier community to respond to customer demand during the outbreak of the H1N1 flu epidemic: http://www.rollstream.com/news…/

Readers of this article might also be interested in a good book about Social Supply Chain Management:

http://www.amazon.de/Social-Su…

Hi Michael,

I completely agree with you, nothing will ever replace the relationship, that's just a basic tenet of business. I'm curious how else real time response can occur if not pro-actively identified by the organization itself through social channels, where else can you get real time data in such a way? You're right on with the discussion about having a “system” that allows all of this to happen (nothing like this exists that I know of yet…right?).

Based on the client work and research I've been doing social media data is definitely creating functional silos. I like to use a CRM system as the ultimate repository of client information to help close that loop.

I agree with you on that, we might see organizations tinker around here and there with social data and interactions but on the whole it's just a “neat” concept

I think the community aspect of the social supply chain is definitely a realistic one (heck you guys are doing it already!) but as a while with all the pieces in play I'm wondering how it can really work.I think William stated it below “a bit of a stretch in reality.” Do you agree?

I think collaboration is a big part of the social supply chain but as with anything “social” it's really hard to identify and explain what a social supply chain really is.

Hello Jacob,

in all humbleness I do believe that there exists a system that allows for such an interaction with customers, partners and across functional divides in an organization with a repository being the key to consolidate all contextual business content, data and processes: http://isispapyrus.wordpress.c…

While traditional CRM systems may be helpful in some way they lack the underlying business architecture for a truly consolidated approach and usually come with a technology stack that is hard and costly to maintain and gives business users little to no power over their processes and hence to make decisions based on their judgment and expertise to fulfill specific goals.

Hi Michael,

I think you probably know more about the subject than I do, the social supply chain area is a bit new for me, but something I find very interesting and related to what I do. I'm definitely not as technical as you are either 🙂

I'm curious to find out more about this system you're talking about

Pingback: Collaboration in the Supply Chain, Where is it?

It’s a good start Jacob, to show the basics of where Cloud Community Business Management can interact and improve the classic SCM processes, data and procedures. But as you point out, it starts from here to define the needs for individual supply chains, industry sectors, even individual companies and their extended enterprise or total value chain. As Michael Zobel is pointing out, the outcome of any social interaction and demographics can only become useful if it is integrated in existing datastreams and processes by matter of alerts into the routine SCM processes. The reference point to integrating Social SCM into the equation is Collaborative SCM. Both need to find common ground to extend into the variables identified in social added value for the parties. There is still a long way to go, but the potentials may be to great benefit to the various participants in the value chain.

Best regards,

Joris Claeys

ACCELERATE-gscs

CAPix-Asia

Port[Expertise]

Jacob,

I missed this article when it was originally posted. I would have loved to have been involved in this conversation as it is near and dear to my heart. The Social Supply Chain has arrived. It differs slightly from your article so I’ll try to explain what it is and why it allows the transformative shifts everyone expects.

First, it is made of three components: Legacy Enterprise Software (any ERP, Best of Breed or Homegrown software – regardless of age or sophistication), Next Generation Enterprise Software and Social/Collaboration Platforms.

Legacy applications are at the heart of every company. They are large, complex, rigid and they aren’t going anywhere. Nor should they go anywhere. As Klenahan said 7 months ago, “Despite years of investing significant time and effort in ERP and eProcurement solutions, many Global 2000 organizations continue to face a fundamental challenge – they cannot collaborate effectively with their business partners.” I will extend that to say these same companies cannot make changes to the transactions that drive their Supply Chain. These systems were not made to change; they were made to consolidate. Yet in business, change is constant, pervasive and permanent.

Companies have been trying to steer their business with these systems and have found that to modify, integrate or replace them is a nightmare. The average age of these systems is 11.5 years old (Constellation Research) and yet companies spend $250B/year (Gartner) on these applications.

So the First Step in a Social Supply Chain Strategy is to leave them alone. Don’t modify, integrate or replace them. Perform a version freeze on what they are today so that their current value or ability to consolidate isn’t lost. Regardless of the version or those of your Vendors or Customers they all use “standard” elements to interact with workers. These can be printed documents (Purchase Orders, Manufacturing/Work Orders, etc.), green-screen computer screens or perhaps formatted files such as xml or spreadsheets.

These worker interaction elements become the point at which the Next Generation of Enterprise Software connects with the legacy systems. Because this new software, provided by companies such as BabbleWare (http://babblewareinc.com), is legacy system agnostic it becomes an instant surrogate for the transaction the ‘old-school’ system requires. It can enhance the transaction by de-coupling the data, process and technology of the legacy app so that the worker is more productive and accurate and the result of their work is more visible. New data and an updated process can be delivered by the worker through the new technology and the legacy application is blissfully unaware that anything is different. In some instances, the transaction that used to be performed by a worker can now be enhanced and handled directly by the new software.

The Second Step in a Social Supply Chain Strategy is to enhance the transactions of the legacy systems within your company and at your Vendors and Customers. This facilitates frictionless collaboration between departments and Supply Chain partners so that the rising tide of productivity, accuracy and visibility raises all boats. The individual transactions that comprise the supply chain can now be improved together AND the results/impact measured and monitored in real time.

This brings us to the Social/Collaboration Platforms. Business requires security so tools such as Google+, Chatter and Yammer each provide the required framework. The Next Generation of Enterprise Software, with the details of critical transactions being executed within it, can now share data in real time to these Social networks. As an example, a Major Account team could coalesce around the transactions that impact their customer. They can identify the ‘filters’ they want the Next Generation software to apply to the underlying transactions so that they can be informed of variances or success.

This brings us to the Third Step in a Social Supply Chain Strategy. Since the new enterprise technology is able to bridge the legacy applications without disruption between Employees, Vendors and Customers these teams can begin to Collaborate. Not only in monitoring and reacting to events messaged to the social network but also in on-going improvements. The knowledge of employees is often never captured and understood/leveraged by the company. As the Collaboration team works together they will identify optimal responses and strategies that are more effective that others. This knowledge is now institutionalized and available to be shared with other teams. New opportunities to improve existing transactions or create entirely new ones can also be developed in these teams. Concept to prototype to results in a matter of hours is a powerful tool to have for any team.

These three steps: 1) Freeze Legacy 2) Enhance Transactions & 3) Unleash Internal Expertise; provide the agility, ease of use and innovation that consumer technology has taught us so well. The Social Supply Chain is not about eavesdropping on consumers. Instead, it connects the many moving pieces of the SuppyChain so that it acts like a single entity regardless of the ‘player’. Reacting to unexpected events that require a fire drill will diminish and the knowledge workers/subject matter experts can continue to focus, refine and improve the performance.

Social supply chain solutions actually help fill the gap that exists between manual and transactional business-to-business processes and as a result are being used to enable real-time response to customers or suppliers.

Very informative post…………….Thanks for sharing with us such a nice information regarding social supply chain management. In nowadays most of the people are using social supply chains for their businesses.

global supply chain management

Its such a nice blog. Its really such a beautiful description regarding the social supply chain, I have come across so far. Its really the beautifully way you have described it and most importantly you have described very beautifully the social chain management.

I think Social Supply Chain is a nice concept. Potential area of application is new demand side like product development and demand management. Supply side can also use social supply chain to interact with broader base of suppliers.

In short, yes I do think it makes sense, but I don’t know of a company that’s effectively using social as part of its supply chain strategy. I also have been kicking this concept around in my head as something more specific – social transportation management. I think as step one, organizations don’t need to plug directly into social channels via APIs (I don’t want my product tweeting for me because it’s passed through an RFID station “Hey everyone, I’m on a #truck!”). Rather, it should be used as a next generation communication method between people – “I have 4 loads that need to get to location X and have had 0 tender accepts. Anyone have capacity?”

Those products should be sending updates to the server, in whatever grouping they are being shipped in (individual unit, pallet, container etc). You wouldn’t be watching all that data, but software could use that data to highlight the issues and trends. As for the article, I don’t quite get the connection to the word “social”, which I think of as people sharing their thoughts and actions with eachother. The concept is good, but I would tend to describe this type of supply chain as an intelligent supply chain that is aware of issues and opportunities and can accommodate changes to make itself more efficient.